Heavy-Duty Industrial Sandblasting Cabinets

That Work As Hard As You Do

High-Quality Abrasive Blast Cabinets and Wet Blasting Equipment

Made in the USA

Raptor Blaster creates industrial-use blast cabinets and sandblasting equipment that helps you get your work done quicker and more efficiently. 100% made in the USA. Subscribe to our YouTube channel channel to learn more about our large capacity abrasive blasting cabinets. Let us know if you have questions!

RB4226 Industrial Abrasive Blasting Cabinet

See why the RB4226 is the best blasting cabinet for small to medium sized objects. 12 gauge steel body, 10 gauge steel doors. Laser cut and hand-welded in the USA.

RB4836 Industrial Media Blasting Cabinet

The RB4836 is the ideal sandblasting cabinet for medium to large objects. Comes standard with a 100 CFM can style dust collector or upgrade to a hard shell cartridge 400 CFM dust collector. 36″ deep, 48″ wide, 75″ high.

RB5446 Large Industrial Blasting Cabinet

The ultimate industrial blasting cabinet for medium to large sized objects. Comes with three 20 watt LED lamps, sturdy 100 CFM BP style dust collector. 46″ deep, 54″ wide, 81″ wide.

RB4836S Slurry System Wet Blast Cabinet

The RB4836S is a heavy duty, industrial-use slurry wet blast cabinet. 100% laser cut and hand welded. Constructed with 12 gauge stainless steel, the RB4836S Slurry Wet Blast Cabinet is designed for durability and everyday use. Two year limited warranty.

RB3630S Slurry System Wet Blast Cabinet

The RB3630S is a heavy duty, industrial slurry wet blast cabinet. 100% laser cut and hand welded. Built with 12 gauge stainless steel, the RB3630S is an efficient blasting cabinet. Perfect for smaller floor plans. Two year limited warranty.

RB4836 Direct Pressure Blasting Cabinet

The RB4836DP is the ultimate Direct Pressure blast cabinet for medium to large sized objects. Laser cut and hand welded 12 gauge steel, made in the USA.

RB900DP Direct Pressure Blasting System

A complete Direct Pressure Blast System which incorporates a 1.5 cube Blast Pot with a high quality Micro Metering Valve, RB900 Reclaim and RB900 Cartridge Style/Timed Reverse Pulse Dust Collector into the one unit.

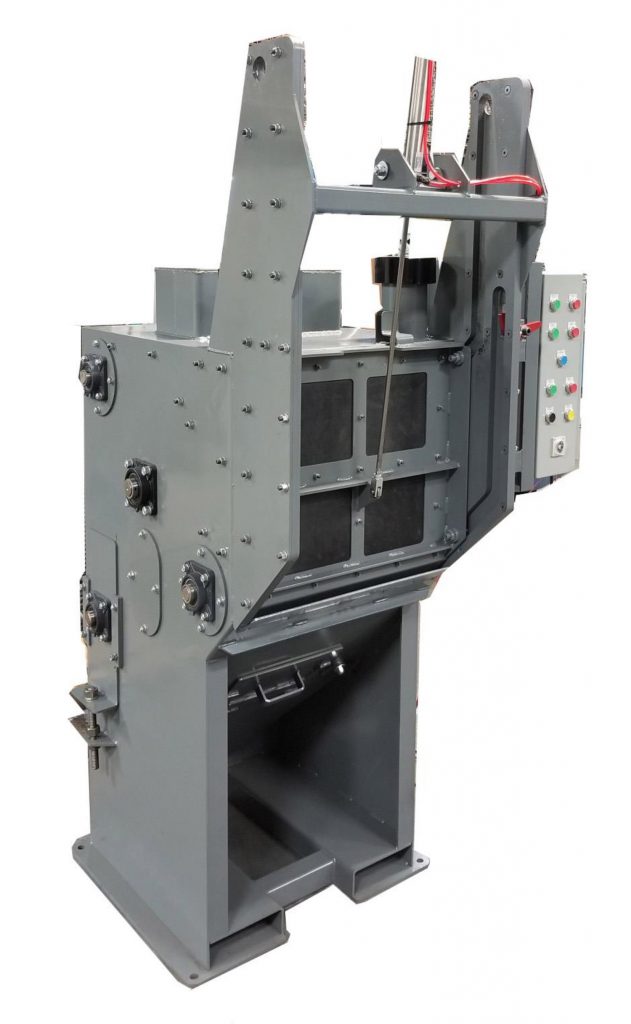

1.5 Air Cube Tumble Blaster

The 1.5 Air Cube Tumble Blaster lets you blast and clean objects while you do other tasks. Three stationary #6 spray nozzles, pneumatic vertical lift door w/ two-button safety, 200 lb. mill capacity, Dial type adjustable cycle tier.

Dust Collectors and Reclaims for Blast Cabinets

We have a wide selection of dust collectors and media reclaims for sandblast cabinets.

Financing is Available

You can finance your purchase through our partner, Paramount Financial. Visit their site for full details.

Raptor Blaster Featured on Motorhead Garage

Why Choose Raptor Blaster Sandblasting Cabinets?

Large Capacity Abrasive Sandblasting Cabinets

Raptor Blaster’s sand blasting cabinets have large highly accessible doors for ease of use. There is one on each side, and a front flip up door for larger and heavier objects on the RB4226 model. Unlike most of our competitors, our blasting cabinets are constructed to keep the abrasive media inside the sand blast cabinet and off the floor. This helps you maintain a safe and clean work environment. We also take pride in our high quality dust collection and LED lighting systems, which allow for the best sandblasting functionality and visibility in the market.

Blast Cabinets Made in the USA with Quality Construction

Blast Cabinets Made in the USA with Quality Construction

Raptor Blaster sand blast cabinets are made in the USA with the highest quality materials and craftsmanship. Our abrasive blasting cabinets are powder coated inside and out with a distinctive dark gray hammertone finish. Built with 14 gauge steel and 10 gauge doors, Raptor Blaster bead blast cabinets have no riveted seams like other media blasting cabinets. All our seams are welded for superior quality. Solid construction and high performance set our blast cabinets apart.

Blast Cabinets Engineered for Durability and Ease of Use

Blast Cabinets Engineered for Durability and Ease of Use

Raptor Blaster’s abrasive blasting equipment is designed and engineered to out-blast and outlast the competition. All our bead blast cabinets are foot pedal (treadle) operated, and come complete with a moisture trap, pressure regulator, and gauge. Built for the industrial market and hobbyists who desire a high quality sandblasting cabinet. A Raptor Blaster blast cabinet will enhance any production facility, shop, or garage.

We proudly design and engineer our own abrasive blast cabinets.

Each model contains features for increased productivity, durability, and operator safety. We always use top-of-the-line components, like BNP style blasting guns (with your choice of ceramic or tungsten carbide nozzles), and high-quality Wilkerson regulators. Our mission is to manufacture trouble-free sand blasting cabinets that will last for years. Here at Raptor Blaster, “Sandblasting Equipment Built for the Industrial Market” is more than a slogan, it’s a promise.